NEXT EXIT: CIRCULARITY

FREITAG INITIATES CIRCULAR TRUCK TARP VENTURE

Zurich’s bag makers have had enough of half measures and cycles. So, in the future, to ensure their tarp bags aren’t merely recycled but are also endlessly recyclable, FREITAG is venturing outside the bag universe to work with selected industrial partners on the development of a truck tarpaulin that fully meets circularity criteria. FREITAG is looking forward to closing its own material cycle soon, and helping to make European road freight traffic just that little bit greener.

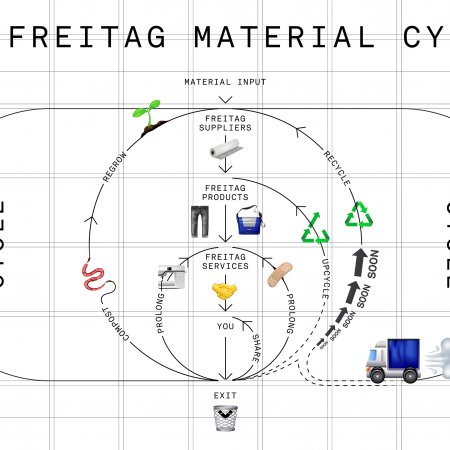

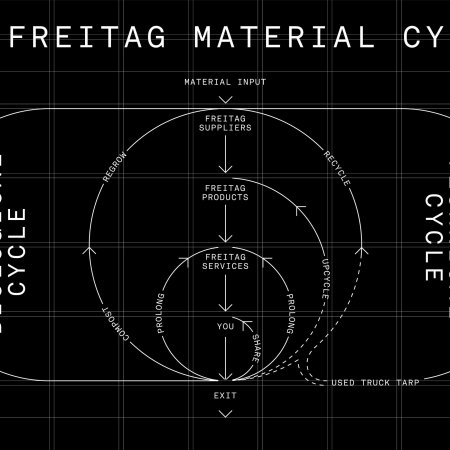

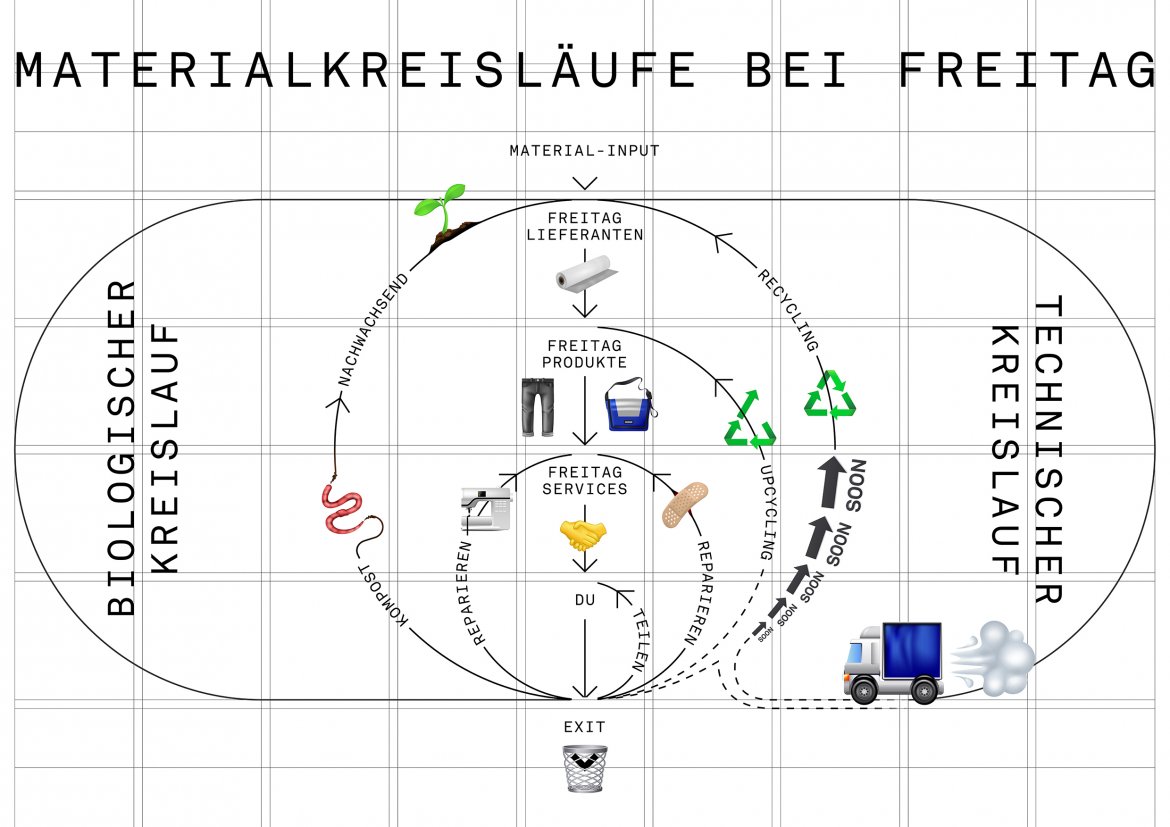

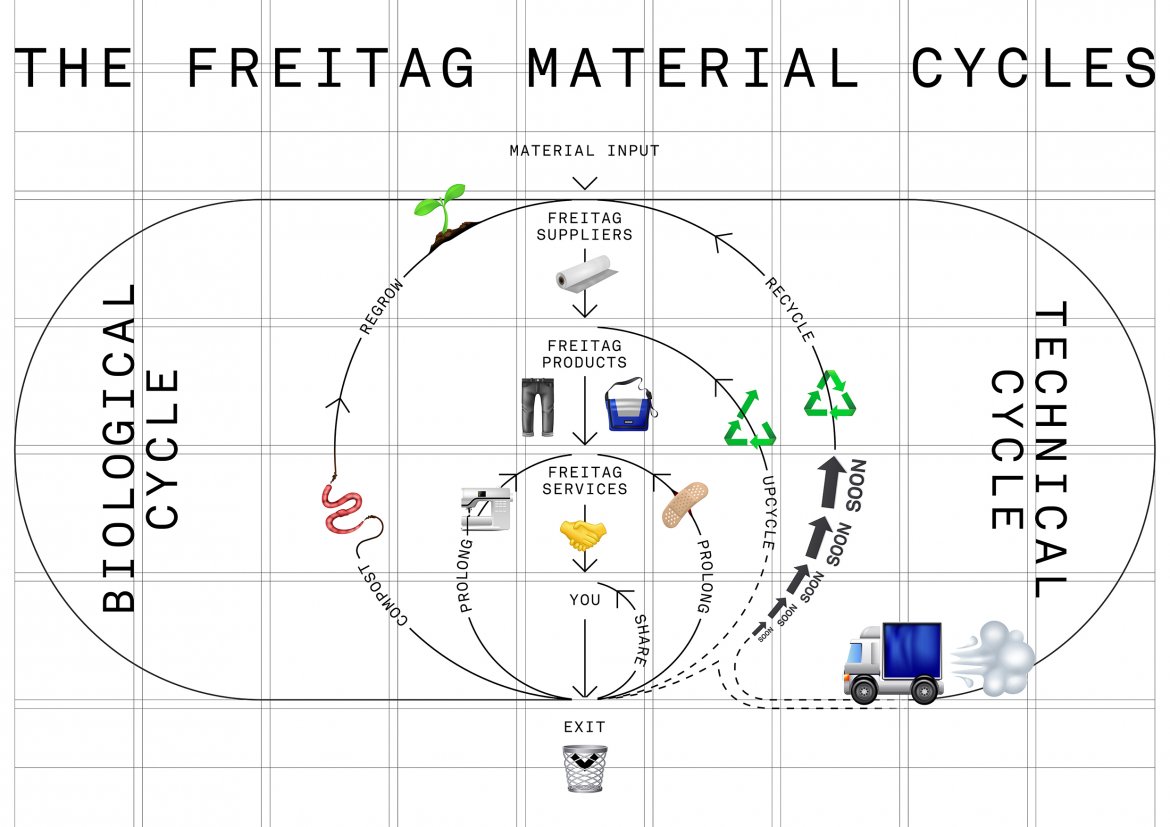

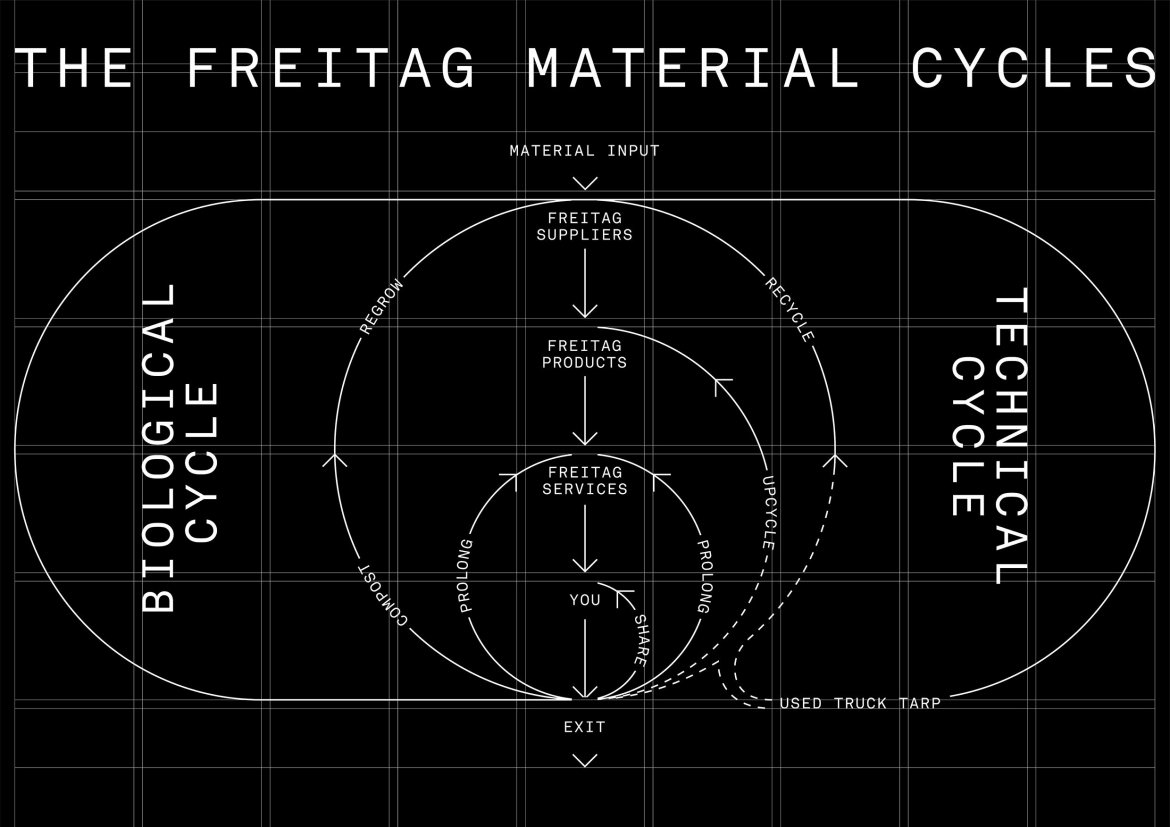

We think and act in cycles: it’s been FREITAG’s corporate philosophy for more than 25 years now. «Today, we’re focusing mainly on how we can give the road transport industry upstream of us a circular material. That would also enable us ourselves to act in endless cycles», specifies Daniel Freitag. In the case of textiles, FREITAG has already achieved this pioneering feat with a 100% compostable clothing line called F-ABRIC, which it developed from scratch.

After five to ten years on the road, and as part of FREITAG’s core business, truck tarps are given a new, long lease of life as bags. This is further extended by repair services and an online exchange platform. But at some point, even the toughest bag gives up the ghost. And when that finally happens, it’s down to the last exit to the garbage incineration plant. «In Zurich, this at least generates a bit of district heating for our tarp bag-making headquarters», says Markus Freitag. “But we’d doing one better, of course, if we could give discarded truck tarps not only a second life, but an everlasting one.”

A little over a year ago, FREITAG decided to set the wheels in motion and start developing a new type of tarpaulin that would meet strict circularity criteria. The envisaged material would, of course, be just as robust, durable, water-repellent and practical as the existing one made of PVC. Instead of ending up in the trash, the new tarp would eventually end up in a biological or technical cycle, which means that one day it will biologically decompose or be broken down into technical constituents from which new tarps or other products can be made.

As part of this quest in an as yet unknown area, FREITAG has now filled the internal role of «Circular Technologist» twice over. Using contacts such as trucking companies and tarpaulin assemblers from the company’s everyday operations, the project team trawled the tarp supply chain in search of interesting and interested partners who could bring the required expertise regarding materials, chemicals and composite to the table. Together with companies and institutions in the fields of circularity and materials testing, the resulting heterogeneous collective of highly motivated partners brings a flexible, goal-oriented, multi-track approach to the tarpaulin revolution. FREITAG’s role in this could best be described as that of a provider of ideas, inspirational force or spiritual co-driver.

Pretty soon, it became apparent that even a new circular tarp would be constructed similarly to existing materials. It would consist of a robust fabric and a soft, water- and dirt-repellent coating made of a synthetic or organically based plastic. The big question, then, still is: How can these two main components be broken down – jointly or separately – into their constituent parts and reused or composted? The collective has already found some partial answers to the question in possible materials and various compounds.

To ensure that each manufacturing step and chemical component genuinely meets circularity criteria, an innovation partner, EPEA – Part of Drees & Sommer, evaluates them using the Cradle to Cradle® method*. «By placing such an uncompromising demand on the concept of circularity, we are not exactly making things easy for ourselves», says Anna Blattert, one of two Circular Technologists employed by the Zurich bag manufacturers. Nevertheless, the team already has initial material prototypes – combinations of different fabrics and coating materials – at its disposal. In tests carried out so far, these have generated surprisingly positive results. «I’m particularly pleased to say that, in some cases, the biologically based coating material has outperformed even conventional synthetics in practical stress tests. We definitely want to stick to this path, even if it involves considerably more development work», explains Bigna Salzmann, likewise a Circular Technologist at FREITAG.

«The entire transport and logistics industry is confronted with disruptive changes. Autonomous trucks, digitization and electric propulsion are radically changing transport logistics. What the industry lacks is a closed-cycle material with future viability. That's where we spring into the breach. And as residual recyclers of the material, we are driven by a certain degree of self-interest», says Oliver Brunschwiler, Company Lead. FREITAG firmly believes that a circular form of tarpaulin will be a reality on transit routes in the foreseeable future and is doing all it can to ensure that a first tarp prototype can be fitted to a truck as early as 2022. All the same, it is difficult to predict when a fully circular tarpaulin will go into series production and when it will be possible to say that the truck tarp cycle has gone full circle. But if FREITAG has any say in the matter, it shouldn’t take much longer. After all, it will take at least another five long years of transit before bags can finally be cut from them: the first FREITAG bags to emerge from the closed tarpaulin cycle.

If you want to know more, you can find out everything that isn’t «tarp secret» (excuse the pun) at www.freitag.ch/circulartarp. And if you’re already looking forward to your first everlasting tarp bag, you won’t miss a trick if you have a subscription to the FREITAG newsletter.

*EPEA - Part of Drees & Sommer evaluates materials using the Cradle to Cradle® method, focusing on comprehensive material health for humans and the environment, technical recyclability and the implementation of a take-back system.