Media Overview

From truck till bag

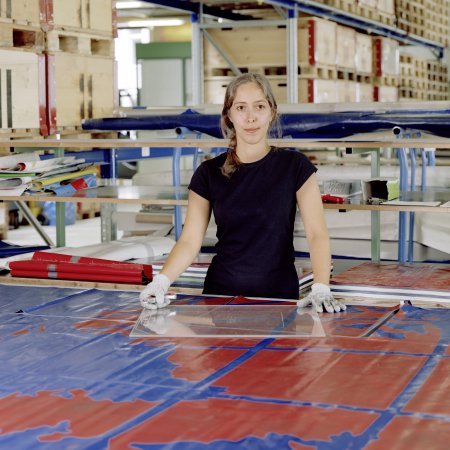

The recycling of used truck tarps into unique, highly functional bags takes place in five highly complex steps at our factory.

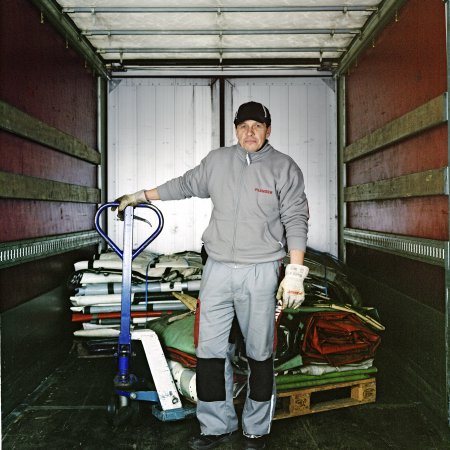

1. Raw materials

Each FREITAG bag produced today is still made from used truck tarp. Finding old tarps for 400,000 FREITAG products annually is no easy task, however. It takes a logistical offensive headed by a four-member team that brings 350 tons of used tarp material back to the factory each year after tracking it down from Sweden to Portugal. Once they arrive at the factory, the tarps are tested for their constituents to ensure that the safety of FREITAG products can be guaranteed.

High resolution download

Auch wenn alle am liebsten die seltenen FREITAG Unikate in Schwarz oder Pink hätten, wir nehmen gerne auch rote Planen. / Foto Credit: Joë Tettamanti

Die endlosen Jagdgründe unserer Truckspotter.

Der ist noch zu jung. Erst nach 5 bis 10 Jahren auf der Transitstrecke sind die Planen reif.

Auch kleine Anhänger können schöne Planen haben.

Jährlich finden etwa 500 Lieferungen von 350 unterschiedlichen Lieferanten ihren Weg ins Nœrd.

Danke für die Planen!

Please mention the Photo Credit: Joël Tettamanti

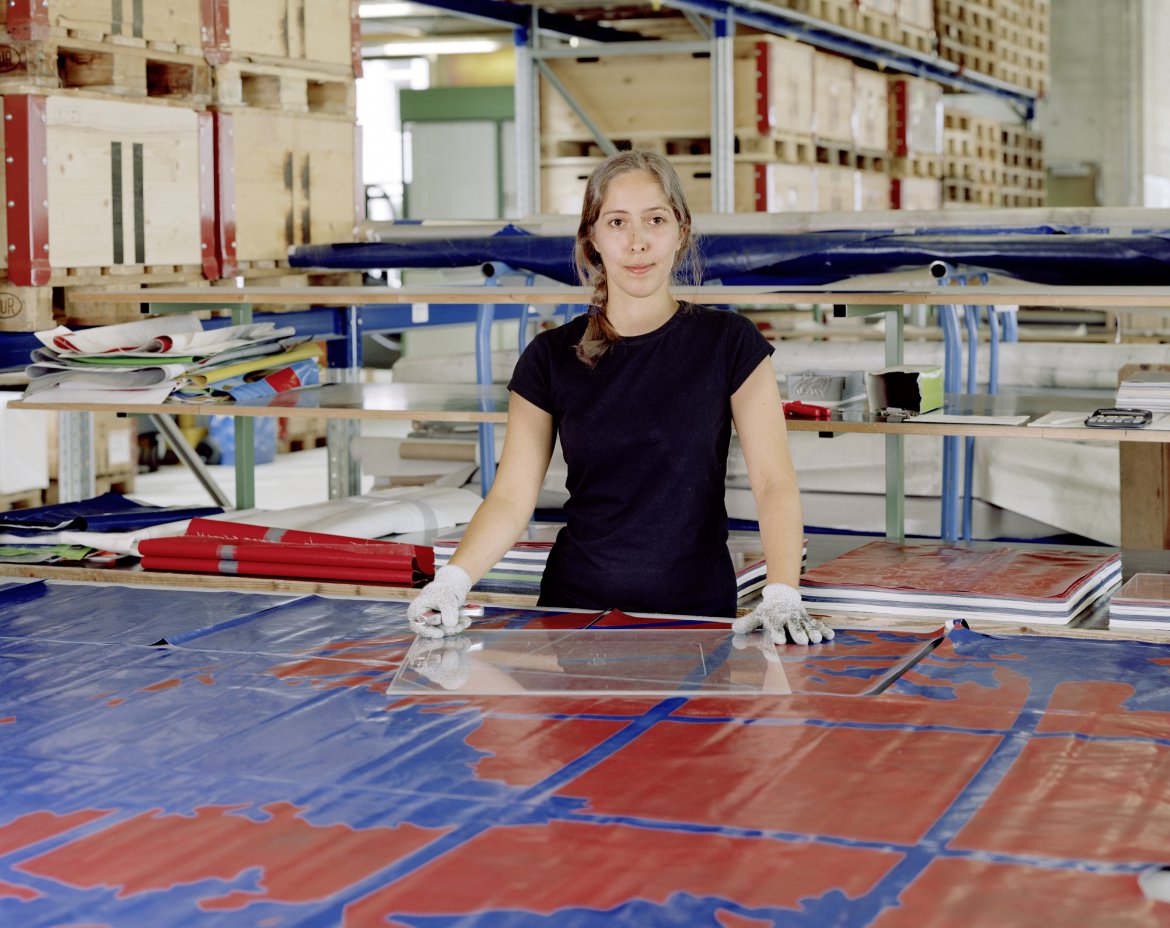

2. Cutting the tarps

In order to turn grimy garbage from the roads into the right raw material for a desirable bag, fearless tarp butchers are needed at the outset. With cutters, pliers and raw force, they free the bulky tarp beasts from their cords and fittings and then slice prime cuts from them. It’s tough work!

High resolution download

Willkommen im Schlachthaus.

Der Zerleger bei der Arbeit.

Ösen und andere Metallteile mögen wir gar nicht. Sie werden rezykliert.

Zerleger filetieren mit dem Cutter.

Zerleger brauchen Kraft und Handschuhe.

Fertig zerlegt und gefaltet.

Wir produzieren «just in time». Für «bad times» haben wir aber trotzdem ein paar Planenschätze im Lager.

3. Washing

What happens in our basement is almost identical to any other laundry room. Our three gigantic washing machines strip all the grime from the roads off the tarp pieces, revealing their unique patina. Because we use over one million gallons of water a year for our laundry activities, we collect rainwater from the roof of the factory and warm it up using the residual heat from the leftover dirty water. The clean tarps then make their way to the drying room instead of a power-hungry dryer.

High resolution download

Die Plane einer FREITAG Tasche hat mit 50-prozentiger Sicherheit genau 50 Minuten in der linken Maschine verbracht.

Zirka zehn Planenstücke teilen sich eine Maschine.

Jeder Waschgang bei 65 Grad braucht zirka 500-600 Liter Wasser, das sind fast 15'000 Liter täglich. Gut waschen wir mit Regenwasser vom Dachgarten.

Aufhängen, nicht tumblern!

Und ab in den Trockenraum.

Mustapha arbeitet jetzt übrigens nicht nur in der Wäscherei für uns, sondern auch auf Instagram: www.freitag.ch/feed

Hier wird jede Plane fotografiert. (Für die Bag Designer, nicht für Instagram)

Ab ins EG zum Bag Design.

4. Bag Design

FREITAG has a whole bunch of different designers. Like other companies we hand the creation of new models to the actual design department. But at our factory, the job of cutting up tarps is part of the design process, too. Each bag pattern consists of several templates. Our bag designers lay these out on the tarps in such a way that as many bags as possible, each as beautiful as the next, can be cut from the raw material. This is what makes every FREITAG bag unique.

High resolution download

Hier arbeiten die härtest-arbeitenden Designer der Welt.

Das einzige, was unsere Bag Designer mit allen anderen Designern dieser Welt verbindet: Sie tragen gerne schwarz.

The First Cut is the Deepest.

Stücke, die es nicht auf die Tasche schaffen, freuen sich auf ein nächstes Leben als iPhone Sleeve oder Shoulder Pad.

Das Halbrunde muss ins Eckige. Oder: eine Tasche für Vierteljapaner.

Nummeriert, gestapelt,...

... und ab in die Nähereien.

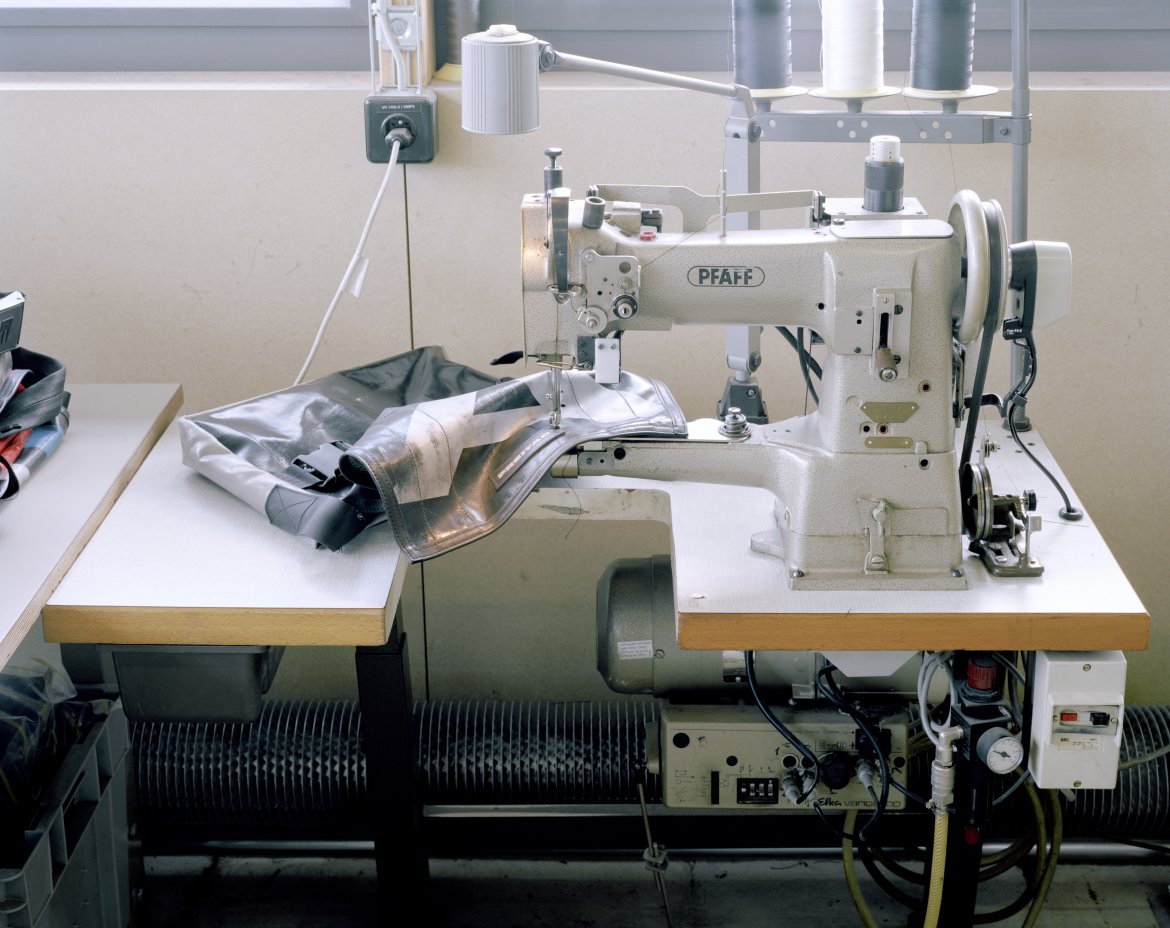

5. Sewing

Now it’s time for the cut tarp sections to leave the factory. They go to our longstanding partners in Portugal, Czechia, Bulgaria, Romania and Switzerland, where sewing machines rattle away stitching the individual pieces into robust products designed for tough, everyday use. When the finished bags return to the factory, they undergo a series of exacting quality-control tests before being dispatched to stores worldwide or being photographed as unique, individual items for presentation in the Online Store.

High resolution download

Wir nähen nur die Prototypen selbst in der F-abrik. Aber bei unseren Partnern sieht das etwa ähnlich aus.

Planen sind zäher als Leder: Harte Arbeit für Nähmaschinen...

Und harte Arbeit für Näherinnen.

Nach rund einem Monat kommen die fertigen Taschen wieder zurück nach Hause.

Qualitätskontrolle: Den Augen der F-Crew entgeht nicht der kleinste Fehler.

Die Taschen in Kisten im Lager.

Der Offline-Bereich des Online Stores.

Say Cheese!

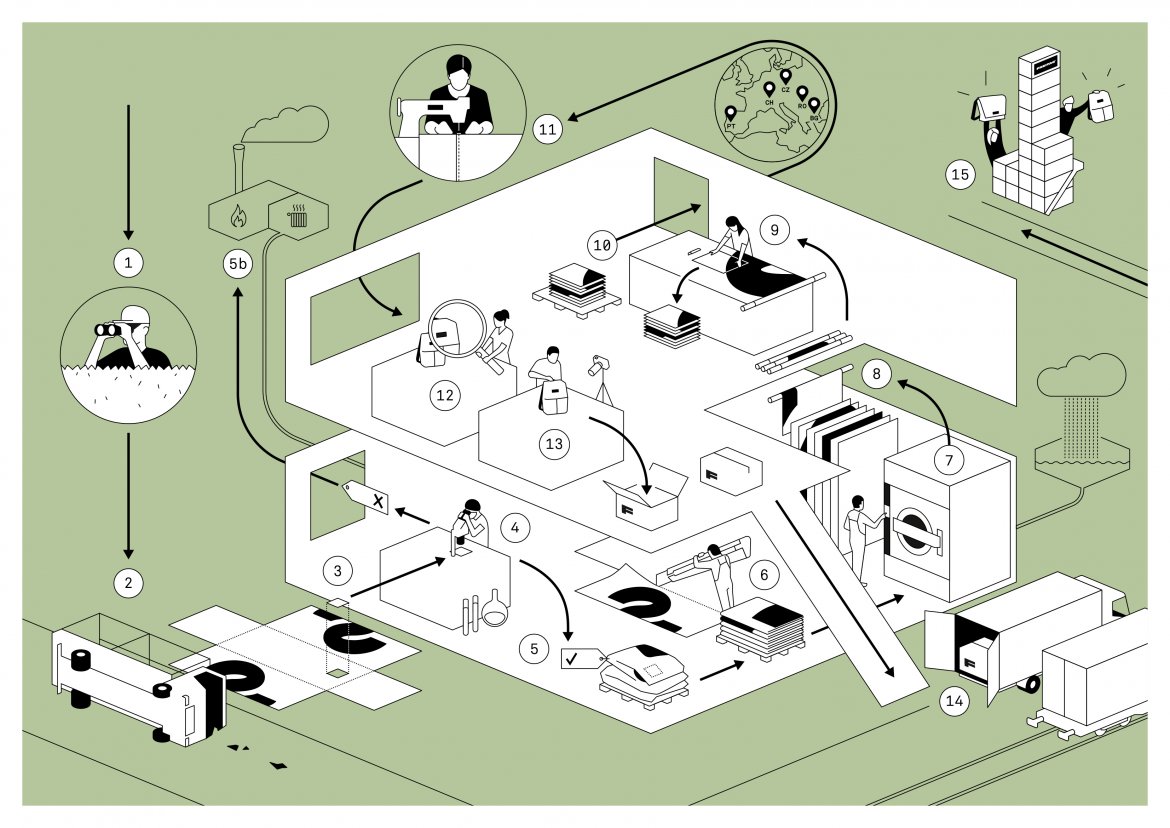

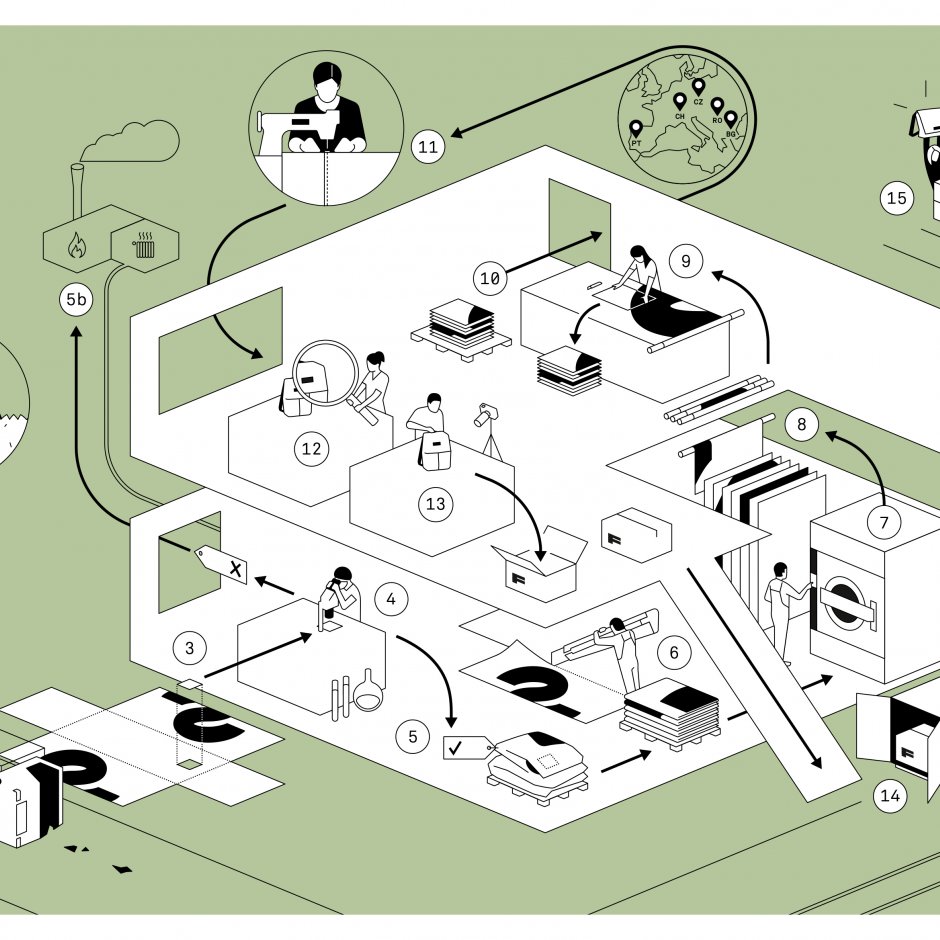

LESS TEXT - MORE STEPS

FREITAG’s one-of-a-kind bag production process for process engineers, flowchart fetishists, icon idolizers and all the other info junkies who prefer visual learning to reading:

1. Truck spotting

2. Tarp removal

3. Extract test sample

4. Testing constituents

5. Confirming that tarp is safe

6. Disassembly

7. Washing

8. Drying

9. Bag design

10. Shipping to sewing partners

11. Sewing

12. Quality control

13. Photography

14. Shipping

15. Sale

1. Truck spotting

2. Tarp removal

3. Extract test sample

4. Testing constituents

5. Confirming that tarp is safe

6. Disassembly

7. Washing

8. Drying

9. Bag design

10. Shipping to sewing partners

11. Sewing

12. Quality control

13. Photography

14. Shipping

15. Sale

Using recycled materials and short transport routes in our supply chain keeps our carbon footprint comparatively low. In 2022, it amounted to 3402 metric tons of CO2 equivalent, or about 480 flights around the world. Along our entire value chain, we are actively working to further reduce our direct and indirect greenhouse gas emissions. If you want to know more about other measures we’ve introduced over the past year and our future plans, you can find out all about them in the first FREITAG Impact Report.