From Truck Till Bag

By Daniel Freitag in the category From Truck Till BagSTEP 1: TRUCKSPOTTING

It’s hard to believe with the endless columns of trucks out there on the transport routes, but used truck tarps aren’t just lying around on the street. And especially not the really good ones. Sourcing raw materials for FREITAG may not be Glencore but it is definitely hardcore. To ensure that our 250 F-Workers always have something to do and to eat, our five tarp buyers – also known as truck spotters – have to find and bring back approximately 800 tons of tarps to Nœrd each year. To accomplish this, the truck spotters are on the phone non-stop, or prowling around the truck stops of Europe to hunt down the best tarps in the hottest colors from trucks, truckers and shipping companies. Once they arrive at the F-actory, the tarps are given an ID for traceability and their constituents tested so that we can guarantee the safety of our products.

That one is still too young. Tarps need five to 10 years on the road to become fully mature.

Even small trailers can have beautiful tarps.

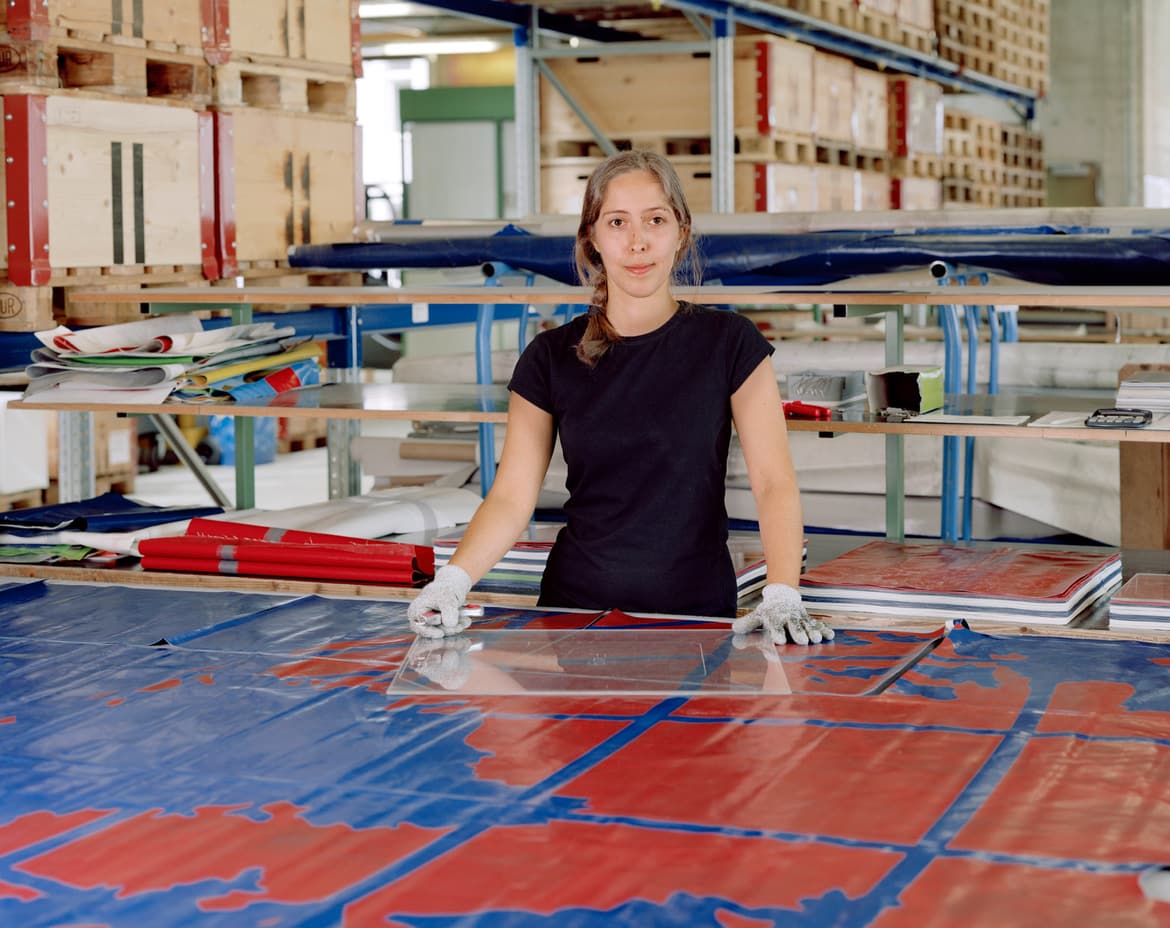

STEP 2: CUTTING TARPS

We manufacture “just in time”. We store a few tarp treasures in our warehouse for “bad times”, too.

STEP 3: WASHING

Hard Work @ Nœrd: Scrubber – Watch the Clip!

STEP 4: BAG DESIGN

Hard Work @ Nœrd: Bag Design – Watch the Clip!

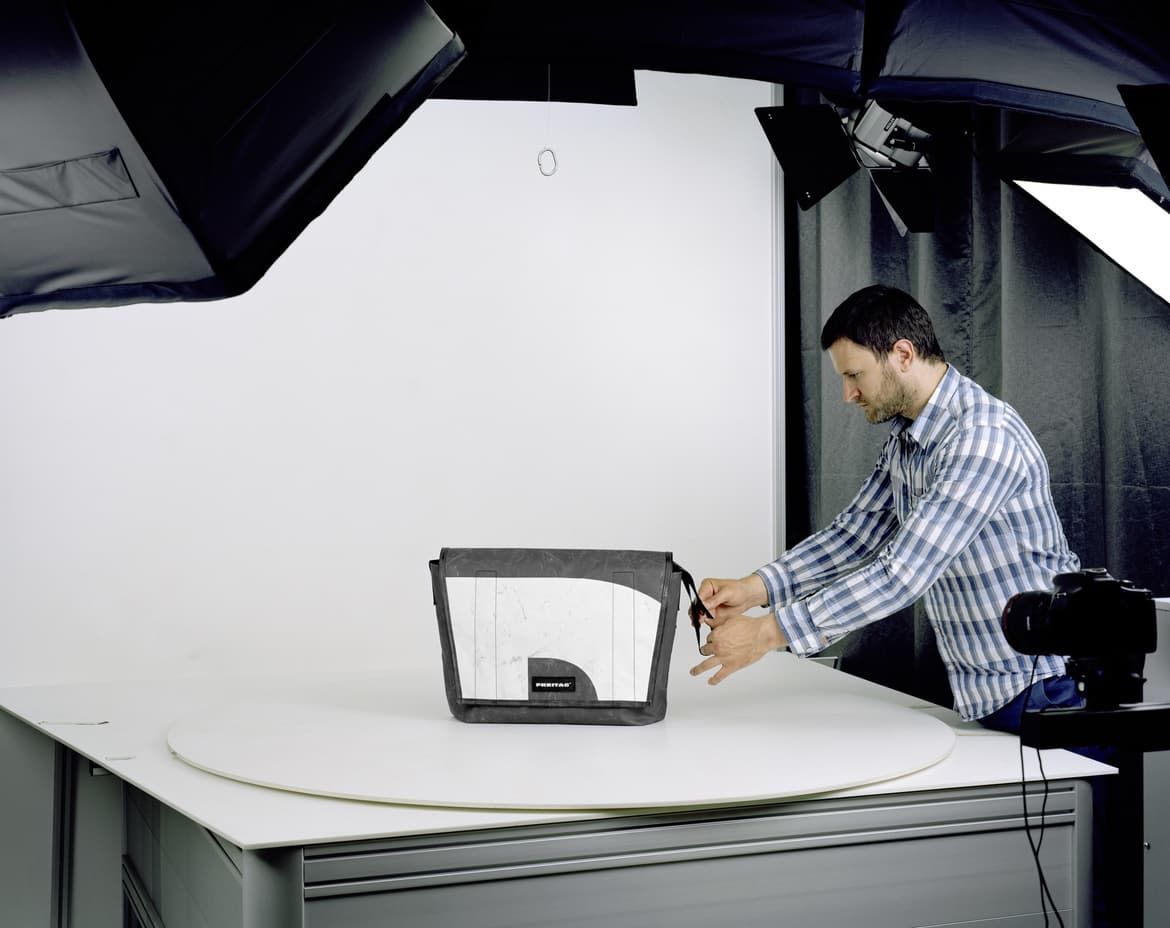

STEP 5: COMPLETION

Say cheese!