FREITAG makes bags and accessories from used and, increasingly, circular materials, too. Something that started in Zurich in 1993 with messenger bags made from discarded truck tarps now comprises a range of backpacks and crossbody bags as well as a wide variety of accessories, each a one-off.

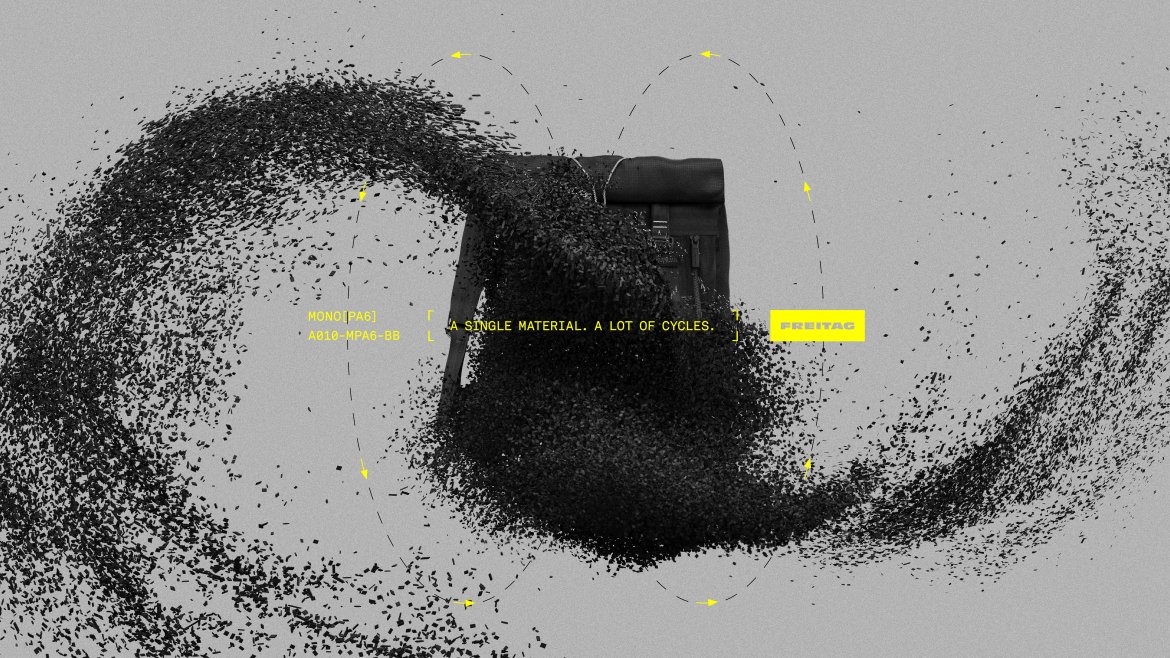

Thinking and acting in cycles is integral to FREITAG’s DNA. Drawing on holistic product design and well-thought-out repair, exchange, and take-back services, we aim to extend the life of bags and accessories or even close material cycles. This has already been achieved with the development of the F-ABRIC compostable clothing line or our circular alternative to short-lived smartphone cases. Launched in 2024, the Mono[PA6] Backpack marks another milestone on the road to acircular economy. And because it is made of a mono-material, it is the first FREITAG backpack that is fully recyclable. And the research continues: Together with industrial partners, FREITAG is working towards the development of a truck tarp that, even after a long second life as a bag, doesn’t end up in the garbage but back in the cycle.

With their use of unconventional materials, the bag-makers continue to surprise. Discarded tarps, car seat belts, and bicycle inner tubes continue to play a major role, but used PET bottles, salvaged airbags, and worn-out ski boots now all contribute to the diverse range. Additional, life-extending options are increasingly taking center stage: In addition to repair services and the chance to design your own bag, the S.W.A.P. exchange platform also ensures that FREITAG products are used and loved for as long as possible. With inspiring initiatives and conspicuous campaigns, such as No to Black Friday and bag loans, FREITAG repeatedly succeeds in drawing attention to its vision of a circular future.

So how did it all start? In 1993, graphic designers Markus and Daniel Freitag were looking for a robust, water-repellent bag to hold their creative work. Inspired by the multicolored heavy traffic that rumbled through the Zurich transit intersection in front of their apartment, they developed a messenger bag from used truck tarps, discarded bicycle inner tubes, and old car seat belts. This is how the first FREITAG bags took shape in the living room of their shared apartment. What began as the idea of two brothers was soon to conquer the world of bags from Zurich across Europe and all the way to Asia.

Today,250 people are employed by FREITAG lab. ag. Over 50 of them work at the Zurich-Oerlikon headquarters, dismantling, washing, and cutting truck tarps, among other things. The one-off bags and accessories are assembled by long-standing production partners in Portugal, the Czech Republic, Romania and Bulgaria, and also by a work integration program in Zurich. The bags and accessories are available in 30 FREITAG stores, from over 300 retail partners in around 25 countries, and at freitag.ch.

FREITAG has not only committed to the circular economy but is also organized in circles: in 2016, the company, which is still owned by the Freitag brothers, abandoned the classical hierarchical structure and replaced it with Holacracy, a form of organization based on self-management.

IN SHORT

WE THINK AND ACT IN CYCLES

FREITAG makes bags and accessories from used and, increasingly, circular materials. What began in Zurich in 1993 with messenger bags made from discarded truck tarps now comprises around 60 models, every product a one-off. FREITAG products are robust, functional everyday companions that, thanks to a range of repair and exchange services, can expect an even longer, more fulfilling life.